Electronic Autocollimators

ELCOMAT Product Line

®

Note: The VP AKD is an electronic autocollimator used with a laptop or desktop for greater flexibility with data collection and analysis.

Note: ELCOMAT 3000 replaced with ELCOMAT 5000

ELCOMAT PRODUCT LINE

ELCOMAT Software

Möller-Wedel Optical GmbH offers different types of software for your application or measuring task with a product of the ELCOMAT product line.

®

SOFTWARE

INCOLINK

Software interface for the transfer of measurement data from devices of the ELCOMAT® product line (except ELCOMAT direct product line) to the computer, time-controlled recording of measurement data, simple integration into customer's own software (e.g. EXCEL®) possible due to universal interface.

Note: Executable under Windows® and the INCOLINK software is generally included in the scope of delivery of an ELCOMAT® products.

Art. No. Description

219 739 INCOLINK Software interface

SOFTWARE

ELCOWIN

The Windows software ELCOWIN from company OEG Messtechnik GmbH is used to measure straightness, squareness, parallelism and flatness of guideways with an electronic autocollimator of the ELCOMAT product line (except ELCOMAT direct product line). The measured values of both measuring axes of the ELCOMAT® (horizontal and vertical) are recorded and evaluated simultaneously. The transfer of measurement data is usually automatic and software-controlled, but manual data entry is also possible as an option.

Note: Executable under Windows®

Art. No. DescriptionLanguage

219 735 ELCOWIN Software German

219 736 ELCOWIN Software English

Measuring Principle

The geometry data are basically determined from the location-dependent changes of the inclination angles of the paths. These serve as input values for ELCOWIN. With the autocollimation method used here, the location-dependent tilting of a reference mirror relative to the optical axis of the measuring system is measured simultaneously in two axes. The measured angle values serve as input data for the evaluation software. From these data ELCOWIN calculates the deviations of straightness, perpendicularity or parallelism of the guideways depending on the measuring task. The measuring accuracy is only determined by the accuracy of the ELCOMAT® (generally <= 2 arcsec) and the environmental influences.

Operation

ELCOWIN is characterized by easy use and first class software ergonomics. For different measurement problems the operator can create custom-tailored measurement templates. Furthermore ELCOWIN enables the editing, evaluation and storage of the measurement results as soon as whose expressive representation in measurement records and free configurable and scalable graphics. There are interfaces to edit and evaluate the measurement results with additional applications (text processing, spreadsheets etc.) via the Windows® clipboard or the creation of textfiles.

For an customer-friendly using of ELCOWIN and a easy measurement design it is possible to save all measurement and evaluation parameter in configuration files.

Measurement Process

The measuring process is largely controlled by the software. Before each measurement, a measurement template must be loaded or newly created in which the parameters start point, end point, interpolation point distance and the number of measurement axes used are defined.

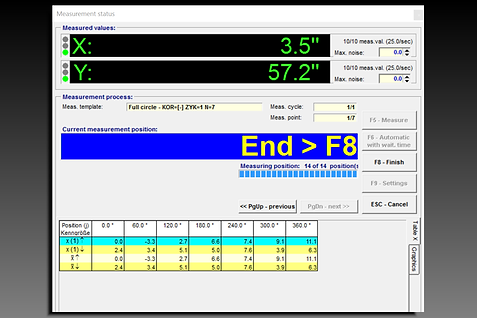

Status Window

The status window shows the progress of the measurement. After starting the measurement, all essential information about the measurement is displayed in the status window. This includes the current measured values and, depending on the status, the current or next position of the reference mirror. Obvious erroneous measurements at individual measuring points (outliers) can be corrected later by repeating this measuring point.

The measured values can be transferred either manually, by remote control, automatically (time-controlled) or manually.

Presentation

The results are presented from within the program in the form of freely configurable diagrams and measurement protocols. The measured values can also be exported as ASCII files. The protocols are compatible with word processing programs. This also provides interfaces to higher-level applications.

To compare different measurements, any number of measured value files can be displayed graphically in a diagram, naturally with freely selectable display parameters for each measurement.

SOFTWARE

RTM

RTM is a software for measuring the position uncertainty and positioning accuracy of rotary tables (rotary tables) according to VDI/DGQ 3441, VDI 2617, ISO 230-2 in connection with electronic autocollimators for measured value acquisition.

The software RTM, in connection with an electronic autocollimator e.g. of the ELCOMAT product line (except ELCOMAT direct product line) and one or more angle standard(s) (polygon mirrors), enables the metrological acquisition and display of pitch errors and wobble errors as well as the calculation of the position uncertainty and positioning accuracy of rotary tables of all kinds.

RTM is a new development and has been adapted in layout and operation to the ELCOWIN applications (software for 2D machine geometry measurement of straight and even guideways by means of electronic autocollimators), which have been successfully marketed for many years.

Note: Executable under Windows®

Art. No. Description

219 743RTM Software

Measurement and Evaluation

The acquisition and evaluation of the measured variables with the RTM software complies with the recommendations of the VDI/DGQ and ISO230-2 guidelines for the assessment of rotational positioning accuracy and offers the following functionality:

-

definition of the measuring (nominal) positions on the measuring object as full circle or pitch circle with fixed angle difference (also > 360°), or completely freely selectable

-

securing and consideration of known, position-dependent errors of the used angle standards (polygon mirrors), if applicable

-

storage and consideration of the known (by certification) position depending errors of the used angle reference (polygon mirror)

-

support of the linear, pendulum and pilgrim step positioning, optionally bidirectional and unidirectional

-

measured value transfer from autocollimator manually with remote control or via external triggering (incorporation of customer-specific solutions)

-

manual measured value input possible

-

saving of all measurement parameters in measurement templates for convenient repeatability of measurements, especially with different measurement objects

-

evaluation according to the evaluation guidelines VDI/DGQ 3441, VDI 2617, ISO 230-2 (current version; further evaluation guidelines can be retrofitted on request)

-

alculation and output of all parameters required according to the evaluation directive, e.g. systematic deviation, backlash, repeatability, position deviation, position uncertainty (Accuracy)

-

textual and graphical evaluation in measurement reports based on the selected evaluation guideline with freely definable protocol text templates, on request also with customer-specific design (e.g. company logo etc.)

-

output, copy and print functions for the measurement protocol or individual components (protocol text, graphics, measurement tables)

-

password-protected software service mode to prevent accidental changes to settings and parameters