GONIOMETERS

Semi-Automatic Goniometer

The GONIOMAT M is a semi-automatic goniometer with electronic image evaluation that is indispensable for measurement and testing of angles of optical components such as prisms, polygon mirrors and gauge blocks in testing laboratories and workshops, as well as for receiving and final inspection. Furthermore it can be used for measuring and testing of angle gauges.

Goniometers

Semi-Automatic Goniometers

If you would like to explore other types of Goniometers, click on one of the buttons just below in the header.

SEMI-AUTOMATIC GONIOMETERS

GONIOMAT M5 / M10

The GONIOMAT M series is available in two levels of accuracy:

-

GONIOMAT M5 class: 1.5 arcsec

-

GONIOMAT M10 class: 2.5 arcsec

Through combination of the newest camera technology, MÖLLER-WEDEL OPTICAL standard components and our innovative software concept the following improvements are achieved:

-

simple adjustment of the test prism surface to the optical axis of the autocollimator

-

automatic clearing of the autocollimation image with the angle encoder

-

the mechanical tilting table is replaced by a "virtual" tilting table thus eliminating the need for time consuming adjustment of a mechanical tilting table

Measuring Tasks

Measurement Tasks

Measurement of plane angles of prisms, especially of 90° prisms

-

Angle measurement of polygon mirrors

-

Measurement of wedge angles

-

Angle measurement of micro prisms

-

Measurement of angle gauge blocks

-

Evaluation of deflection angles

-

Measurement of pyramidal angles

-

Measurement of refractive indices / Determination of glass-types

-

Measurement of prisms with protective coating

-

Measurement of roof edges

Advantages

Measurement Tasks

-

Short measurement times

-

Elimination of the subjective rate by electronic image evaluation

-

Logging of measurement results

-

Easy handling

-

Portable due to the compact design

SEMI-AUTOMATIC GONIOMETERS

GONIOMAT M5 XL

MÖLLER-WEDEL OPTICAL has expanded the GONIOMAT M product series with the semi-automatic GONIOMAT M5 XL for measurements of very large prism and plane optical components with a maximum diameter of 250 mm. The height between optical axis and top edge of the supporting table is 90 mm. All other significant technical data correspond to the well-known GONIOMAT M5 Goniometer.

For more detailed Information about 'GONIOMAT M5 / M5 XL / M10' follow the link below.

Technical Data

* according to DIN 1319

** four measurements on 90° rotated encoder positions required; sample surfaces λ/4 P.V., 30x30 mm

*** with the use of a 3-point base

Scope of Delivery

Besides the actual instrument each delivery consists of:

-

Connection Cable

SEMI-AUTOMATIC GONIOMETERS

Extension for Ground Prisms

The patent pending extension for ground prisms for the GONIOMAT M5/M10 Goniometers allows the measurement of prism angles with a fine grinding / roughness of up to Rq = 1.0 µm and a measurement uncertainty of less than 10 arcsec. The achievable accuracy and measurability of the test specimen depends on its surface size, and its roughness.

EXTENSION FOR GROUND PRISMS

Time and Cost Savings in the Production Process

The manufacture of precise optical prisms is time-consuming and requires appropriate manufacturing and metrological expertise. During fine grinding, an appropriate basic angular accuracy of the prism must be achieved, as the material removal during polishing is much lower than during grinding. During the polishing process only the fine correction of the prism angles is carried out. If the required basic angle accuracy is not achieved during fine grinding, this is usually only visible after polishing the measuring surfaces. Either adequate material reserves are still available to correct the prism according to the drawing with a further fine grinding and to finish it during the subsequent polishing, or the prism must be written off as production scrap. Until now, there was no easy and quick to use precise measuring device to measure the angular accuracy of ground prisms before polishing. The use of an appropriate measuring device holds a high potential for saving time and costs in the production process. In addition, the system can contribute to the optimization of the fine grinding process and thus to quality improvement.

Technical Data

* Accuracy depending on surface size and roughness of the specimen

SEMI-AUTOMATIC GONIOMETERS

Typical Applications

With the goniometers of the GONIOMAT product line a multitude of parameters of plano-optical components can be tested and measured. An overview of the typical application possibilities can be found here.

TYPICAL APPLICATIONS

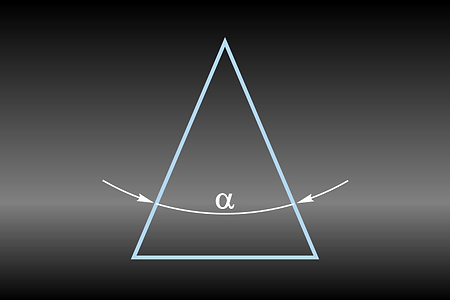

Angle Measurement

For mass production of prisms and angle gauge blocks the measurement of angular accuracy can take place on the production floor. In addition, the pyramidal error to the base will be determined. The software can report both: the result of a single measurement and the mean and distribution values of productions lots. this information can be used to verify production consistency.

TYPICAL APPLICATIONS

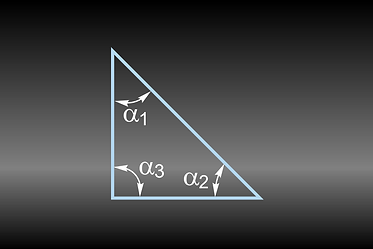

Prism Measurement

All angles of a prism can be measured for compliance to technical specifications in one measuring sequence. The reflections of all prism surfaces are detected. Afterwards surface, pyramidal and deflection angles are calculated. Pyraqmidal error can be reported according to any various ISO definitions, depending on the application. the deflection angle can be reported for any wavelength, not only for the measurement wavelength. Setting a tolerance level makes incomming and outgoing inspection easier.

TYPICAL APPLICATIONS

Polygon Mirror Measurement

During polygon mirror measurement the angle between the surfaces of a polygon are determined according to VDI 2605. The software reports the cumulative angle error, the angle error relative to the first face and between adjacent faces. The software also includes the rossete method, which has the smallest measurement uncertainty. In addition, the pyramidal error can be reported.

TYPICAL APPLICATIONS

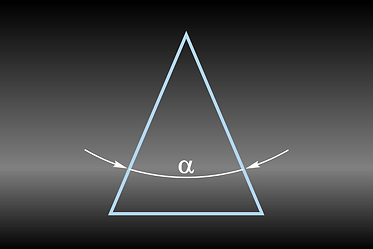

Wedge Angle Measurement

Three evaluation methods are available for the measurement of plane-parallel windows or wedges: The evaluation of the double image in reflection, measurement by turn-around, measurement against a mirror in transmission. The evaluation method used depends on whether the user requires a fast measurement, a refractive index-independent measurement or a high-accuracy measurement, respectively. The orientation/direction of the wedge will be given for all the methods. This can be used for marking the thick side of the wedge. Additionally, the deflection angle can be calculated by the software.

TYPICAL APPLICATIONS

Deflection Angle Measurement

The deflection angle can be measured for all planar optical components and assemblies. Similar to the wedge angle measurement, there is a high-accuracy method, a simple method and a fast method available. The high-accuracy method is comparable to the measurement principle of the "Reeve" method, published in NBSIR 76-993 by NIST. In contrast to the "Reeve" method, the report of the deflection angle is defined according to ISO 10110.

TYPICAL APPLICATIONS

Beam Splitter Cube Measurement

The angle of the internal surface of a polarizing beam splitter cube can be measured. The internal angles are determined by the evaluation of multiple reflections at the outer surfaces simultaneously with the outer geometry. The software can report the internal angle, the deflection angle in transmission and/or the deflection angle in reflection.

TYPICAL APPLICATIONS

Refractive Index Measurement

For the measurement of refractive index, two evaluation methods are available whose results are based on ray-tracing analysis. The first variant uses the Abbe method and is suitable for refractive angles up to 42°. The second variant uses a double-sided mirror to measure the deflection in transmission, but does not have to be performed at the minimum of deflection. The wavelength of the internal LED is used for measurement and the result is extrapolated to the C'-line. Optionally, a spectral lamp is available as illumination for precise measurements at other spectral lines.

TYPICAL APPLICATIONS

Roof Edge Angle Measurement

A measurement at lacquered surfaces or at roof edges is possible with the roof mode. The measurement uses the information from internal reflections to determine the internal angles. The lacquer does not need to be removed, nor must there be anything attached to the highly sensitive roof edge. So this method alleviates difficulties for both incoming inspection of lacquered prisms and for inspection during production of roof edge prisms.

SEMI-AUTOMATIC GONIOMETERS

Measurement Principle

Each instrument of the GONIOMAT M series consists of a rotary table (1), an angle encoder (2), an electronic autocollimator (3) with USB-connection and the GONIOMATIK software (4).

The clearing of the autocollimation image with the angle encoder is done by the software. Therefore the surfaces only need to be placed coarse to the optical axis of the autocollimator.

SEMI-AUTOMATIC GONIOMETERS

Measuring Process

-

Place the prism and turn the first surface to the autocollimator until the autocollimation image gets visible in the measurement window.

-

Set the measurement position to 'zero'.

-

Turn the next surface to the autocollimator

-

The angle between both surfaces will be indicated as soon as the autocollimation image appears in the measurement window.

SEMI-AUTOMATIC GONIOMETERS

Accessories

MÖLLER-WEDEL OPTICAL offers for your applications or measurement tasks with a semi-automatic goniometer of the GONIOMAT M series the perfect matching accessories.

Here are presented the in scope of delivery and optional offered accessories.

If you need more information, please contact us!

ACCESSORIES

Angle Measurement Standard

Each GONIOMAT M and GONIOMAT A is supplied with an angle measurement standard for on-site inspection and calibration.

Art. No. Description Comment

241 612 Angle Measurement Standard Part of the scope of delivery of GONIOMAT M

and GONIOMAT A product line

ACCESSORIES

Parallel Mirror 2" for Refractive Index Measurement

The refractive index measurement in Abbe-mode is possible for refractive angles up to arcsin (1/n). Thus, the refractive angle is limited to approximately 42°. For refractive angles between 40° and 60°, the refractive index has to be measured in "minimum of deflection" against a double-sided mirror.

Art. No. Description Comment

280 803 Parallel Mirror 2" For GONIOMAT M and GONIOMAT A

ACCESSORIES

Alignment Aid for Micro-Prism

This accessory for the measurement of microprisms facilitates the positioning of test specimens to the autocollimator of GONIOMAT M and GONIOMAT A / A-HR goniometers. Its optical adjustment aid allows a reliable and simple adjustment of particularly small prism surfaces in horizontal alignment up to very small sizes of 0.5 mm².

Art. No. Description

241 616 Alignment Aid for Measuring Micro-Prisms (GONIOMAT M)

241 667 Alignment Aid for Measuring Micro-Prisms (GONIOMAT A-HR)

In addition, the tilting of the prism surface in a vertical direction can be controlled. This is particularly useful if very small microprisms are to be measured, because dust particles between the sample support and the prism base have a large influence on the vertical tilting of the prism surface. This unwanted tilting can be compensated either by cleaning the sample support or by using a special tilting table, which is included in the delivery.

The adjustment aid consists of an adjustment laser to control the tilting angle of the surfaces and a 3-point tilting table which can be used to compensate for the tilting of the specimen in more difficult cases.